Our Pipeline Demagnetizer System includes everything needed to save money by dramatically reducing joint time. By becoming self sufficient with our proven field demagnetizer package, you can immediately control magnetism in the field.

Emergency Repairs

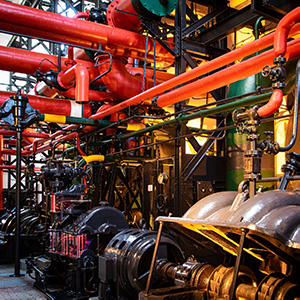

Whether a pipeline burst, delay in laying pipes at sea, or an unplanned outage in a manufacturing facility or a power plant, Demagnetizing Solutions is ready to work side-by-side with your team to get the job done.